pH Control

The term pH describes the acidity or alkalinity of water. A pH of 7 is neutral. Lower values are acidic, and pH greater than 7 is alkaline.

The pH of the incoming water used at municipal and industrial plants changes seasonally – or regularly – depending on storms, or man-made interventions upstream. As a result, pH must be identified and adjusted based on its intended use.

- Municipal plants strive to bring pH levels to neutral (7)

- Industrial plants prefer (and in some cases require) alkaline water (pH > 7) for some applications (such as boiler feeds)

- Some disinfection chemicals used in industrial processes work more effectively at higher pH levels

For a variety of reasons, pH is adjusted, measured and re-adjusted numerous times during the water treatment process.

To neutralize an acid or a base, a source of hydroxide ions (OH-) or hydrogen ions (H+) are required, respectively.

- To lower pH – alkaline water is neutralized with acids (such as Hydrochloric acid or Sulfuric acid) which contain excess hydrogen ions.

- To raise pH – acidic water is neutralized with caustics or bases (such as Sodium Hydroxide, or Calcium Hydroxide/lime), which contain excess hydroxide ions.

Both acids and bases are dosed via metering pumps.

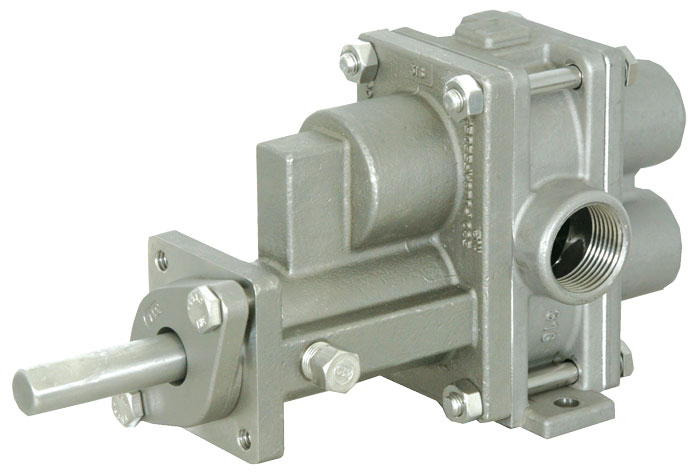

Gear Pumps: In some cases, a uniform and high volume flow of neutralizing agents is required. In these cases, Rotary gear pumps make an ideal and cost effective choice.

Diaphragm Pumps: In other cases, the volumes of chemical required vary widely (depending upon the quality of the source water, and also on the intended use of the process water, post-treatment. In these cases, diaphragm pumps with turndown ratios of 100:1 can deliver accuracy down to +/- .5 percent.

Accuracy Matters:

Most chemicals are procured in concentration, and they must be metered accurately – not just to save money, but also to ensure that over-dosing does not occur.

Corrosion Resistance:

Many of the chemicals used for pH control are harsh in nature, and can be dangerous to plant personnel. The pumps used should be available in 316 stainless steel, Alloy 20, PVDF and PTFE configurations.

Common Products for this Application

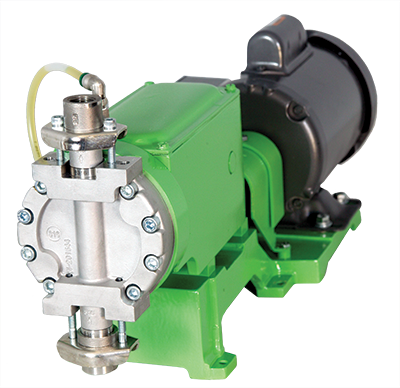

PulsaPro

PulsaPro Series is a perfect fit for Water & Wastewater Treatment, Oil & Gas and Industrial applications.

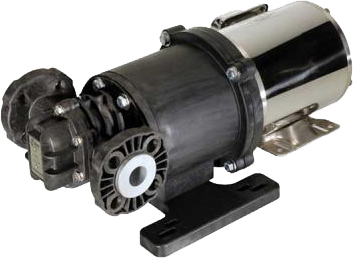

Pulsa Series

From thin fluids to lime slurries, materials of construction for contact with the most hazardous chemicals and features and options to provide safe, remote and accurate dosing, count on Pulsa Series for the most demanding applications.

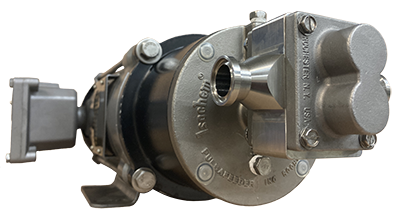

Eclipse

Eclipse rotary pumps are an ideal fit for many corrosive liquids. From acids to bases, we cover the entire pH scale.

ISOchem

Pulsafeeder’s ISOChem Series is a compact rotary gear pump, designed to safely handle highly corrosive, hazardous, explosive, or toxic chemicals in industrial applications.

ECO

ECO gear pumps are well suited for pilot plants, vacuum systems, and metering applications.