Process/Chemical Metering

Metering Pumps are to Chemicals, as Needles are to Medicine

Chemicals make up a “top-3” expense for any plant, and their value to the process is invaluable because chemicals provide the life-blood for industrial and municipal plants. Metering pumps play a key role in dosing chemicals (that are often procured and stored in high concentrations). Although a metering pump is far less expensive than the material it handles – it must accurately deliver precise volumes every time – to ensure proper results for the process.

Pulsafeeder pumps are the preferred choice for metering chemicals in industrial & municipal plants. The most common chemicals pumped include:

Manufacturing:

- Sodium Silicate (for pulp & paper production)

- Ethylene Glycols (for manufacturing plastics, textiles, latex paints, adhesives)

- Vinyl Methyl Ether and Vinyl Monomers

- Nitrate, Ammonium, Urea, Phosphate and Potassium (for fertigation/fertilizers)

- Methanol (MTBE production for petroleum refining and solvent production)

- Hydrochloric Acid (hundreds of uses including PVC production and metal refining)

- Triethylaluminum/TEAL (for manufacturing of plastics, common co-catalyst in olefin polymerization)

PH Control:

- Sulfuric Acid – to lower pH

- Caustic Soda (sodium hydroxide) – to raise pH

- Sodium Bisulfite – for dechlorinating applications

- Lime Slurries – for water softening

Disinfection:

- Sodium hypochlorite

- Calcium hypochlorite

- Hydrogen Peroxide

- Bromine (in cooling tower applications)

- Copper Sulfate (for algae control in cooling tower applications)

- Ammonium Sulfate or aqua ammonia (for chloramines/secondary disinfection)

Coagulation & Flocculation:

- Alum or sodium aluminate

- Ferric chloride

- Proprietary Polymers (provided by water doctors)

Taste and Odor Control:

- Activated Carbon Slurries

- Diatomaceous Slurries (wet and dry applications)

- Fluoride compounds

Heavy Metal Removal:

- Potassium Permanganate (for manganese & iron removal)

- Phosphate (for redwater control)

- Hydrochloric Acid (for numerous applications)

Metering pumps used to deliver chemicals should be selected by criteria specific to the process, such as:

- Flow Rates & Pressure – as required by the process

- Corrosion resistance – to the chemical being pumped

- Accuracy – to deliver precisely the amount of chemical needed for a process

- Reliability – to ensure sustained and predictable operation

- Simplified maintenance – to minimize costs and maximize plant uptime

- Safety – to protect plant employees, and the surrounding environment

This criterion helps to determine whether a diaphragm pump or a rotary gear pump is the best choice for a specific application.

Common Products for this Application

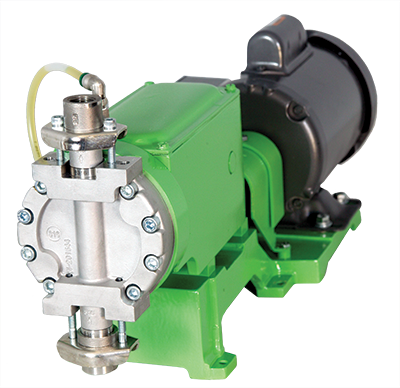

PulsaPro

PulsaPro Series is a perfect fit for Water & Wastewater Treatment, Oil & Gas and Industrial applications.

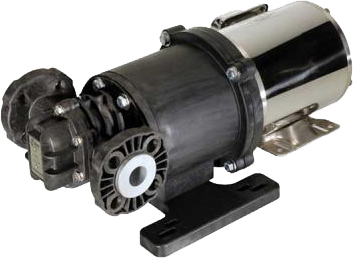

Pulsa Series

From thin fluids to lime slurries, materials of construction for contact with the most hazardous chemicals and features and options to provide safe, remote and accurate dosing, count on Pulsa Series for the most demanding applications.

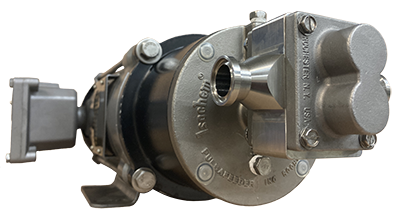

Eclipse

Eclipse rotary pumps are an ideal fit for many corrosive liquids. From acids to bases, we cover the entire pH scale.

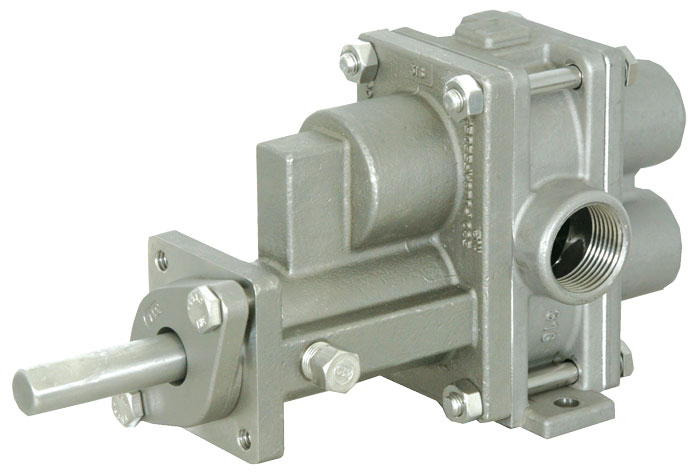

ISOchem

Pulsafeeder’s ISOChem Series is a compact rotary gear pump, designed to safely handle highly corrosive, hazardous, explosive, or toxic chemicals in industrial applications.

ECO

ECO gear pumps are well suited for pilot plants, vacuum systems, and metering applications.