Oil & Gas

The Role Metering Pumps Play in the Upstream Oil & Gas Industry

Metering pumps play a critical role in the upstream oil & gas industry. Flow assurance chemicals such as methanol, monoethylene glycol and corrosion inhibitors must be accurately injected into wells to keep oil & gas flowing, and to boost recovery rates. If these chemicals stop flowing, the well’s production can come to a halt.

Metering pumps are small components on an upstream platform – but the role they play is analogous to a rivet on the wing of an airplane. If that critical component fails, the entire enterprise can be compromised.

Applications

Chemical & Refinery

Petrochemical Upstream & Downstream

API 675 Pump

Alternative Fuels

Triethylaluminum / TEAL

Offshore Production:

For offshore production, one of the biggest issues is the formation of hydrates, which form when light hydrocarbons and water mix under high pressures and low temperatures. Hydrates restrict flow and can damage equipment. Remediation is time consuming, expensive and dangerous (to people, equipment, and the environment), so a sound strategy for managing hydrates is critical. Flow assurance chemicals prevent oil & gas from cooling. They delay the formation of hydrates, and they ensure fluidity from the reservoir to the surface.

Metering pump requirements:

-

Adherence to API 675 standards

-

Accuracy and hydraulic power

-

Reliability is paramount, because the value of a single day’s production exceeds the cost of the pumping systems.

Onshore Oil & Gas Production:

Pulsafeeder pumps are widely used in the Bakken shale region of the United States and throughout the Middle East to deliver flow assurance chemicals. Pressure requirements in onshore environments are far less than offshore requirements (250 Bar is sufficient).

Shale production requires extensive volumes of water, and this water must be treated for use, and prior to disposal. Pulsafeeder metering pumps are also used to treat process water at well sites, and to inject scale inhibitors to protect equipment and pipeline infrastructure.

Metering pump requirements: Safety and security are job one. API 675 standards and government regulations require equipment to be manufactured to the highest standards. Attention paid to preventative maintenance is greater than ever – so equipment must be made to exacting standards to assure long-term safety and reliable performance.

Separation and Pipeline Transport:

Various chemicals, such as asphaltine and paraffin inhibitors are metered in specific doses when oil & gas are separated and transported from platforms via pipelines. These chemicals are expensive (and injecting too much upstream requires removal downstream), so pump accuracy is paramount.

Space, Weight & Efficiency:

When offshore platforms are built, the amount of steel required to support the platform and everything on it (both above and below the waterline) is carefully calculated. Each ton of equipment requires a ton of support steel topside, and two additional tons of support steal below the waterline (at roughly $30,000 per ton). Considering that hundreds of pumps are required on a platform, the weight and footprint of each pump matters.

For accurate injection of chemicals used for process or utility applications in petrochemical plants, PulsaPro hydraulically actuated diaphragm metering pumps can provide the dependability and safety you require.

Pulsafeeder has experience with accurately metering hazardous and non-hazardous chemicals used in producing or metering olefins, catalysts and aromatics in the Petrochemical market. An example of some of these chemicals are:

|

Olefins

|

Aromatics

|

||

|---|---|---|---|

|

Ethylene

|

Propylene

|

C4 Stream

|

Benzene

|

|

Ethylene Glycol

|

Butanol

|

Buadiene

|

Toluene

|

|

Tetrachlorethylene

|

Monomers

|

MTBE (Fuel Ether)

|

Xylene

|

|

DEA

|

Monomers

|

|

Cyclohexane

|

|

MEA

|

MMA (monomer)

|

|

MDI (Methyl diphenyl diisocyanate)

|

|

TEA

|

Butene

|

|

Surfactants

|

|

Polyester Resin

|

Acetone

|

|

Acetone

|

|

Ethylbenzene

|

Acrylonitrile

|

|

Ethylbenzene

|

|

Styrene

|

Cumene

|

|

TDI (Toluene diisocyanate)

|

|

Ethylene Dichloride

|

Propylene Oxide

|

|

Paraxylene

|

|

Solvents

|

Acrylic Acid

|

|

|

|

Diethylene Glycol

|

Isopropanol

|

|

|

|

Acetic Acid

|

Butyl Acetate

|

|

|

|

Ethyl Amines

|

Isophorone

|

|

|

|

Acetaldehyde

|

|

|

|

|

Vinyl Acetate

|

|

|

|

|

Ethyl Alcohol

|

|

|

|

|

Ethanolamines

|

|

|

|

|

Ethylene Glycol Ethers

|

|

|

|

Common Products for this Application

Pulsatron X

Pulsatron X is durable enough for the most hazardous environments with it’s hazardous location ratings and yet precise enough for delicate operations.

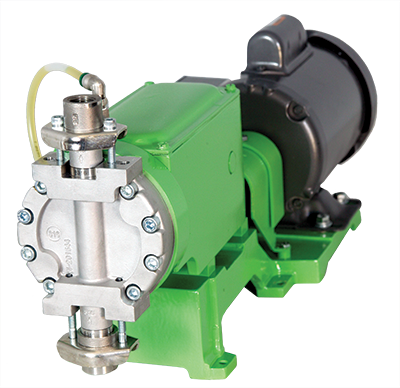

PulsaPro

PulsaPro Series is a perfect fit for Water & Wastewater Treatment, Oil & Gas and Industrial applications.

Pulsa Series

From thin fluids to lime slurries, materials of construction for contact with the most hazardous chemicals and features and options to provide safe, remote and accurate dosing, count on Pulsa Series for the most demanding applications.

Want to talk Petrochemical?

Pulsafeeder works extensively with world’s largest EPC and Petrochemical Companies in Upstream/Midstream/Downstream segments. We understand the process, and the requirements for Petrochemical Industry. We invite you to contact us, we love to talk about the products, packages and support that Pulsafeeder can provide.