Power Generation

How Water is used in Power Generation

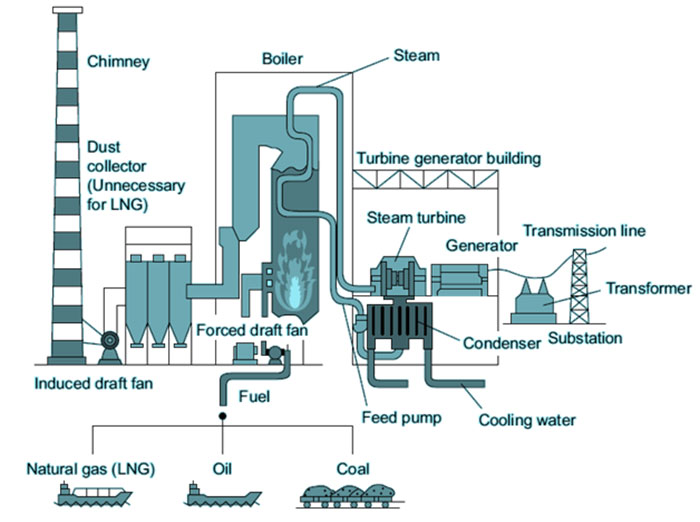

Today, about ninety-percent of electricity generated globally comes from thermoelectric (coal, nuclear or natural gas) power plants. These plants boil water by burning a fossil fuel or through a nuclear reaction to create steam that spins turbines. Steam has to be cooled back into water before it can be reused to produce more electricity. Colder and cleaner water cools steam more effectively and allows for more efficient electricity generation.

How much water do Power Plants use?

- Legacy coal-fired plants, relying on once-through cooling processes need about 30,000 gallons of water for every megawatt of electricity produced.

- Modern plants with recirculating systems can make the same megawatt of electricity with just 5-percent as much water (about 1,200 gallons per megawatt).

- Nuclear plants (regardless of their cooling system) require about twice-as-much water as coal-fired plants.

There’s a direct correlation between the quality of the water and the efficiency of the plant. Incoming water must be treated to remove sludge & sedimentation; dissolve suspended organic material; adjust pH levels; and it must be disinfected to eliminate micro-organisms. These treatments are administered by injecting chemicals with metering pumps.

- Disinfection – is accomplished by dosing specific quantities of high-concentration sodium hypochlorite (bleach), which can be prone to “off-gassing” – so the pumps used must be able to process the gas bubbles without clogging the pump.

- pH adjustment – power plants operate best when the pH of the cooling water is neutral (pH-7). Specific volumes of acids are dosed to alkaline feed-water (pH higher than 7), while caustics are dosed to acidic feed-water (pH lower than 7) to raise its alkalinity.

- Boiler feed-water must be treated with corrosion inhibitors to avoid scaling that could damage or impede the boiler’s performance.

- At the end of a plant cycle, process water must be treated prior to disposal. Flocculation basins are used to dose chemicals that aggregate precipitated particles into larger groups that are easier to filter out.

- Additional rounds of disinfection and pH adjustment are typically rendered by the plant’s wastewater facility before water is discharged into the environment.

Common Products for this Application

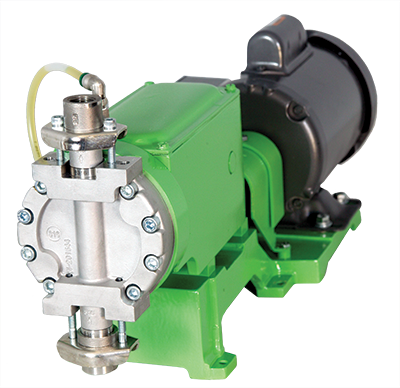

PULSAtron

Typical applications are acids, caustics, polymers, bleaches, pH control, solvents, dyes/ink, catalyst, cleaning agents, and much more.

Pulsa Series

From thin fluids to lime slurries, materials of construction for contact with the most hazardous chemicals and features and options to provide safe, remote and accurate dosing, count on Pulsa Series for the most demanding applications.

PulsaPro

PulsaPro Series is a perfect fit for Water & Wastewater Treatment, Oil & Gas and Industrial applications.

IsoChem

ISOChem magnetically driven sealless gear pumps offer the reliability you need to safely handle clear lubricating and non-lubricating liquids. A wide variety of material options provide versatility for pumping low or high viscosity fluids over a broad range of temperatures and pressures.

Eclipse

Eclipse rotary pumps are an ideal fit for many corrosive liquids. From acids to bases, we cover the entire pH scale.

MicroVision EX

The MicroVision EX is a microprocessor controller used in cooling tower applications.

MicroVision Condensate

The MicroVision Condensate Controller delivers condensate return monitoring with a reliable and accurate temperature compensated conductivity probe.

MicroVision Boiler

The MicroVision Boiler Controller is configured specifically for boiler water control featuring a reliable temperature compensated conductivity probe.

MicroVision Timer

The MicroVision Timer is a microprocessor-based selectable timer controller, designed specifically for timer based control applications.

MicroTrac

The MicroTrac is a microprocessor based feed and bleed toroidal conductivity controller designed to control conductivity and feed inhibitor in cooling tower systems.