Cooling Tower Water Treatment

Pulsafeeder manufacturer's solutions for pH neutralizer or adjustment, disinfection, fluoride and equipment upkeep.

What is a Cooling Tower

- Open recirculating cooling water system used to extract heat from processes or equipment on premises. Examples include air conditioning chillers, industrial processes and related equipment.

- A large device, in the form of a tower-shaped building, in which warm water is cooled by evaporation caused by circulating currents of air

- A cooling system used in industry to cool hot water (by partial evaporation) before reusing it as a coolant

What do Controllers do?

Measure Parameters of industrial processes

- Cooling towers

- Boilers

- Other Processes

Control equipment

- Metering pumps (chemical feed timers)

- Solenoid Valves & motorized valves

Facilitate Data Acquisition

- Download the measurements to a PC

Using MicroVision series of controllers, including our cloud connected MicroVision EX controller and PULSAtron pumps to increase energy efficiency, reduce water consumption, reduce manpower, and optimize chemical utilization by:

- Controlling conductivity to prevent scaling

- Controlling pH by metering acids and caustics to maintain a pH range that prevents corrosion

- Controlling ORP by metering bromine or chlorine to prevent biological growth and fouling

- Controlling inhibitor levels by monitoring PTSA

- Controlling and monitoring corrosion rates using different metal tips like stainless steel, copper, etc.

- Metering inhibitors such as polyphosphates or molybdates to inhibit corrosion

- Timed dispensing of biocides such as gluteraldehyde or isothiazilone to prevent biological growth and fouling

What do we measure?

Conductivity

- The ability of a substance to conduct electric current.

- The basic unit of measure is µS/cm

- Also may be expressed as Total Dissolved Solids (TDS)

Conductivity Control

- As conductivity increases, potential for precipitation increases.

- Scaling reduces system efficiency.

- Conductivity control balances water use and system efficiency.

- Conductivity is reduced by adding lower conductivity water to a system.

pH

- Scientific Definition – Negative Logarithm of hydrogen ion activity in moles per liter

- Practical Definition – measures the effectiveness of acidity of an aqueous solution

- pH is represented by a unitless scale of 0 – 14

- Where 0 pH is acidic, 7 pH is neutral, and 14 is considered very alkaline or a strong base

pH control

- pH imbalance accelerates corrosion.

- pH imbalance reduces chemical effectiveness.

- pH is controlled by adding (pumping) acid or a base into a system.

- Water must be a certain pH to be discharged.

ORP

- Oxidation Reduction Potential or Redox

- Measured in millivolts

- Typically used in conjunction with pH

- Provides an indication of the solution’s ability to oxidize or reduce another material.

Commonly used oxidizers:

- Chlorine

- Bromine

- Ozone

- Sodium Hypochlorite

- Hydrogen Peroxide

Commonly used reducers:

- Sodium Bisulfite

- Sulfur Dioxide

- Ferrous Sulfate

ORP Control

Typically oxidizers and reducers are added to processes such as:

- Water Disinfection

- Bleaching

- Cyanide destruction

- Chrome Reduction

- Metal Etching

- De-chlorination

PTSA

- PTSA is p-Toluenesulfonic acid

- Uses traceable additive for chemical dosing

- Exhibits response to UV excitation

PTSA Control

- Concentrations can be detected and tied to chemical control in a MicroVision EX using a 4-20mA loop and set point control for superior control and less chemical waste

Corrosion Sensor

- The sensor is equipped with different metal tips to gauge the corrosion rates, similar to the Corrosion Coupon Racks.

- Common metal tips

- Mild steel

- Copper

- Can also try other tips like stainless steel, aluminum, or brass.

Corrosion Sensor Control

- Corrosion sensors measure the corrosion rates that the cooling tower material will experience over a period of time.

What is a Cooling Tower

- Open recirculating cooling water system used to extract heat from processes or equipment on premises. Examples include air conditioning chillers, industrial processes and related equipment.

- A large device, in the form of a tower-shaped building, in which warm water is cooled by evaporation caused by circulating currents of air

- A cooling system used in industry to cool hot water (by partial evaporation) before reusing it as a coolant

Common Products for this Application

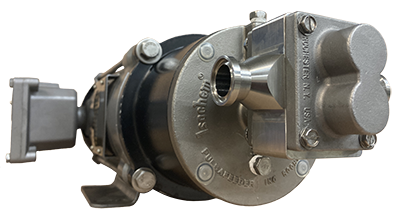

PULSAtron

Typical applications are acids, caustics, polymers, bleaches, pH control, solvents, dyes/ink, catalyst, cleaning agents, and much more.

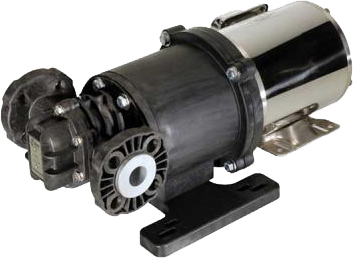

PulsaPro

PulsaPro Series is a perfect fit for Water & Wastewater Treatment, Oil & Gas and Industrial applications.

IsoChem

ISOChem magnetically driven sealless gear pumps offer the reliability you need to safely handle clear lubricating and non-lubricating liquids. A wide variety of material options provide versatility for pumping low or high viscosity fluids over a broad range of temperatures and pressures.

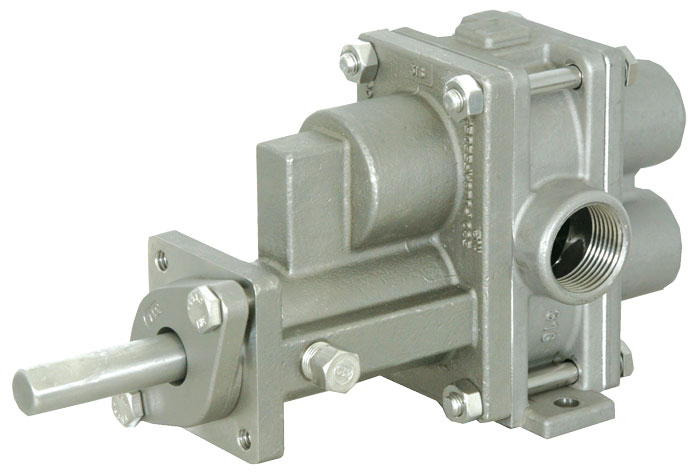

Eclipse

Eclipse rotary pumps are an ideal fit for many corrosive liquids. From acids to bases, we cover the entire pH scale.

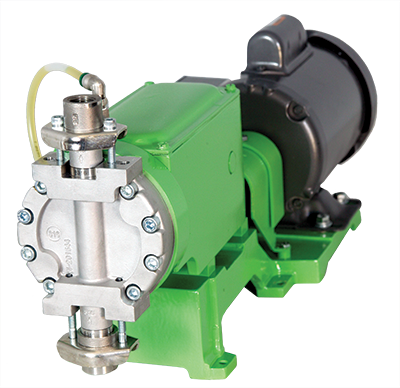

Pulsa Series

From thin fluids to lime slurries, materials of construction for contact with the most hazardous chemicals and features and options to provide safe, remote and accurate dosing, count on Pulsa Series for the most demanding applications.

ECO Series

The ECO Gearchem rotary gear pump is an economical alternative for chemical transfer, cyclic operation and continuous production systems, both open ended and closed-loop. ECO gear pumps are well suited for pilot plants, vacuum systems, and metering applications.

MicroVision EX

The MicroVision EX is a microprocessor controller used in cooling tower applications.

MicroTrac

The MicroTrac is a microprocessor based feed and bleed toroidal conductivity controller designed to control conductivity and feed inhibitor in cooling tower systems.

MicroVision Timer

The MicroVision Timer is a microprocessor-based selectable timer controller, designed specifically for timer based control applications.

MicroVision Boiler

The MicroVision Boiler Controller is configured specifically for boiler water control featuring a reliable temperature compensated conductivity probe.