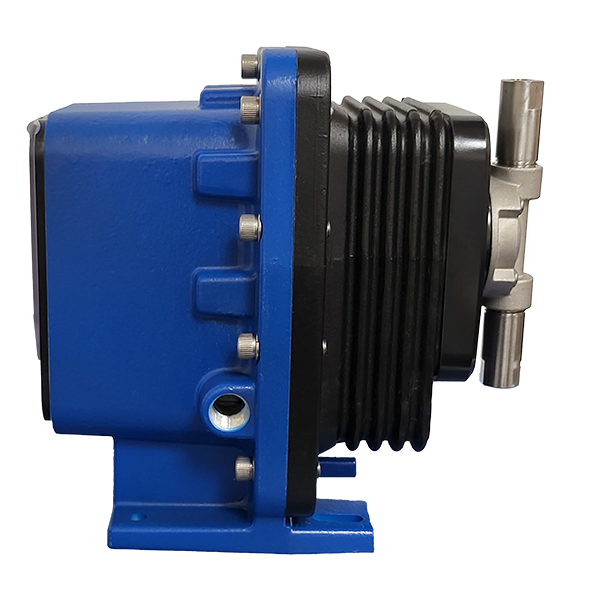

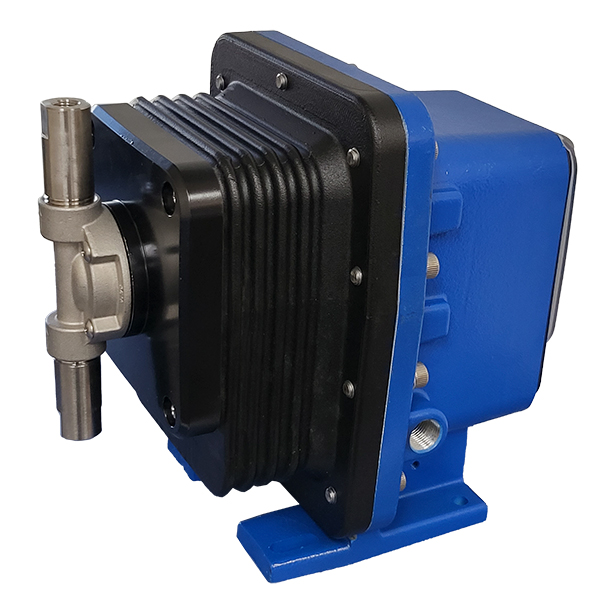

The versatility and chemical compatibility of the industry-leading Pulsafeeder® Pulsatron™ solenoid pump family with certified explosion-proof construction—all in one hazardous location pump. That’s the Pulsatron Series X diaphragm metering pump, available in five models covering flow rates from 31 to 600 GPD and pressures up to 300 PSIG.

Integrated Explosion Proof Pump Design

Proven Pulsatron Reliability

Flexible Control Integration

Operating in hazardous locations means every piece of equipment must meet strict safety standards while delivering dependable, long-term performance. Traditional chemical metering pump solutions often require costly external enclosures, additional certification, and complex installation.

The Pulsatron Series X positive displacement pump eliminates these challenges with an integrated explosion proof design that simplifies system costs and installation complexity while ensuring compliance. Purpose-built for facilities where flammable gases, vapors, or combustible dust create high-risk conditions, this explosion proof pump makes precise dosing safe without external protection equipment.

Certified for hazardous environments across multiple industries

The Pulsatron X—which meets even stringent Class I Div 1 pump requirements—carries comprehensive hazardous location pump ratings, ensuring compliance across diverse classified areas.

Class I, Division 1, Groups C, D, T5 – Flammable gases and vapors

Class I, Zone 1, Group IIB T5 – International hazardous gas classification

Class II, Division 1, Group E – Combustible metal dust

Class II, Division 2, Groups F & G – Combustible carbonaceous and non-conductive dust

Class II, Zone 20, Group IIIC – International combustible dust classification

These ratings mean you can deploy the Pulsatron X explosion proof pump with confidence in oil and gas facilities, chemical processing plants, refineries, pharmaceutical manufacturing, and any environment where explosive atmospheres may occur.

Corrosion inhibitor injection and chemical dosing in classified refinery areas

pH control and hazardous chemical metering in Division 1 environments

Additive injection and corrosion control in explosive atmospheres

Process chemical feed in controlled, classified production areas

Disinfection and chemical treatment in hazardous locations

Chlorine feed and chemical dosing systems in classified environments

Built on Pulsafeeder’s proven solenoid diaphragm pump technology with over 25 years of field-tested reliability, the Pulsatron X delivers precise metering within ±2% of maximum capacity. The rugged aluminum housing provides exceptional corrosion resistance while containing any internal events, ensuring both personnel safety and operational continuity.

Manual stroke rate and stroke length adjustments provide operational flexibility, while guided ball check valves ensure consistent dosing accuracy and outstanding priming characteristics even in demanding applications.

Product Options:

Accessories:

Hypalon® and Viton® are registered trademark of E.I. DuPont Company.

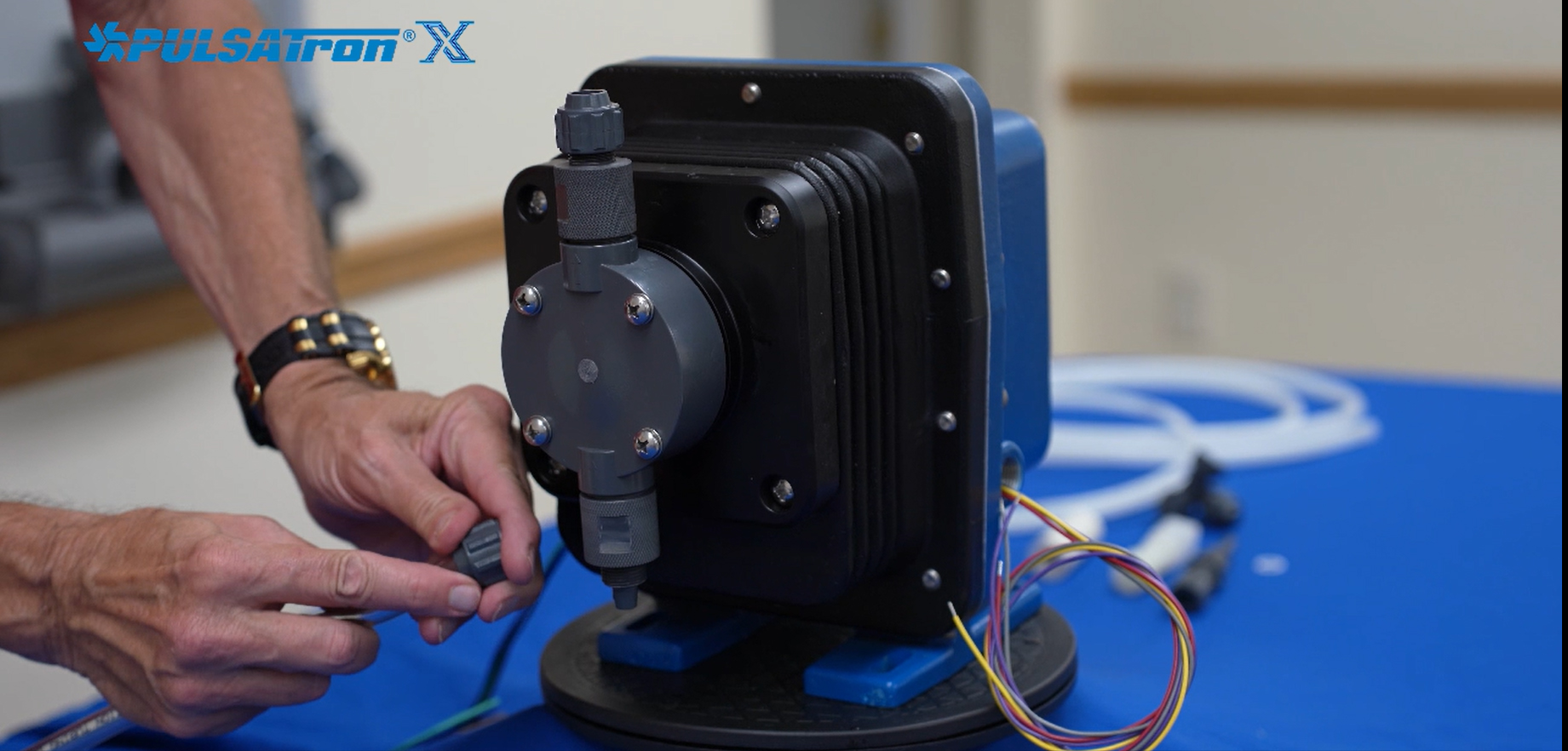

Pulsafeeder Pulsatron X Explosion-proof rated diaphragm metering pump. When safety, compliance, and reliability matter the Pulsatron X Explosion Proof metering pump provides safe feed of chemical into your process.

Pulsafeeder Pulsatron X Series – Priming your pump, will assist you in the best method to prime your metering pump.

Installing Pulsatron X is simple when you follow these video steps.

What makes the Pulsatron X different from standard Pulsatron chemical diaphragm pumps?

The Pulsatron X positive displacement pump features certified explosion-proof construction with a rugged cast aluminum housing designed to contain internal events and prevent ignition of external hazardous atmospheres. Unlike standard Pulsatron models, the X Series carries Class I Division 1, Class I Zone 1, and Class II hazardous location ratings, making it suitable for environments with flammable gases, vapors, or combustible dusts. The integrated control panel eliminates the need for external enclosures required when using non-rated chemical pumps in classified areas, reducing system costs and installation complexity while maintaining the same proven Pulsatron reliability and ±2% metering accuracy.

Do I need an external control enclosure for the Pulsatron X in hazardous locations?

No. The Pulsatron X explosion proof pump has integrated 4-20mA and external pulse inputs built directly into the certified control panel, eliminating the need for separate external enclosures. This integrated design reduces equipment costs, simplifies installation, saves valuable facility space, and ensures complete compliance with hazardous location requirements. Traditional non-rated chemical metering pumps require costly explosion-proof enclosures to house control components—the Pulsatron X eliminates this expense entirely.

Which Pulsatron X model should I choose for my application?

Model selection depends on your required flow rate and system pressure. The Pulsatron X hazardous chemical pump offers five models covering a wide performance range:

XPK4: 31 GPD @ 300 PSIG – Best for high-pressure, low-flow applications

XPH5: 76 GPD @ 150 PSIG – Medium-low flow with medium-high pressure

XPH6: 120 GPD @ 100 PSIG – Balanced flow and pressure for general applications

XPJ7: 240 GPD @ 80 PSIG – Medium-high flow with moderate pressure

XPH8: 600 GPD @ 30 PSIG – High-volume applications at lower pressure

Each model offers 100:1 turndown ratio for precise flow control. Our application engineers can help you select the optimal model based on your specific chemical, flow requirements, and system conditions.

Can the Pulsatron X explosion proof pump handle corrosive chemicals?

Yes. The Pulsatron X chemical injection pump offers multiple wetted material options to ensure chemical compatibility with aggressive fluids. Pump head materials include GFPPL (glass-filled polypropylene), PVC, PVDF (polyvinylidene fluoride), and 316 stainless steel. Check valve components are available with PTFE, CSPE, or Viton seals, and ceramic, PTFE, 316 SS, or Alloy C balls. This material flexibility allows the chemical pump to handle a wide range of corrosive chemicals including acids, caustics, chlorine solutions, and other aggressive fluids common in chemical processing, water treatment, and industrial applications. The rugged aluminum housing provides additional corrosion resistance for demanding environments.

Is the Pulsatron X NSF 61 certified for water treatment applications?

Yes. Select Pulsatron X models with PVDF or PVC materials conform to NSF/ANSI/CAN 61 and 372 standards for potable water contact. This certification ensures our chemical dosing pump meets stringent safety requirements for drinking water treatment applications, making it ideal for municipal water systems, chlorination, and disinfection in classified areas where both explosion-proof ratings and NSF 61 compliance are required. PVDF models specifically carry NSF 61 approval. Always verify material selection meets your specific water treatment regulatory requirements.

What's the difference between Class I Division 1 and Zone 1 ratings?

Both ratings address similar hazards but follow different classification systems. Class I Division 1 is the North American (NEC) standard for locations where flammable gases or vapors are present continuously or frequently under normal operating conditions. Class I Zone 1 is the international (IEC) equivalent standard. The Pulsatron X carries both certifications—Division 1 Groups C and D, plus Zone 1 Group IIB—ensuring compliance whether you’re following North American codes or international standards. This dual certification provides maximum flexibility for multinational facilities or projects requiring either classification system. Both represent the most stringent level of protection for gas/vapor hazards (as opposed to Division 2 or Zone 2, where hazards exist only under abnormal conditions).